ZIP System® Insulated R‑Sheathing

ZIP System R-sheathing is the simple all-in-one structural panel with built-in exterior insulation. Featuring integrated moisture, air and thermal protection, ZIP System R-sheathing completely reimagines traditional wall assemblies by streamlining exterior water, air and thermal management.

01 Products

View Specs

Panel Type[1] | Total Thickness | Panel Size | Panel Count | R-Value | Code Evaluation Report | Air Barrier |

|---|---|---|---|---|---|---|

| 1" | 4' × 8'

4' × 9' 4' × 10' | 32 | 3.6 | ESR 3373

ER 482 | ASTM E 2178 <0.02 L/s●m2) @ 75 Pa ASTM E 2357 <0.2 L/s●m2) @ 75 Pa | |

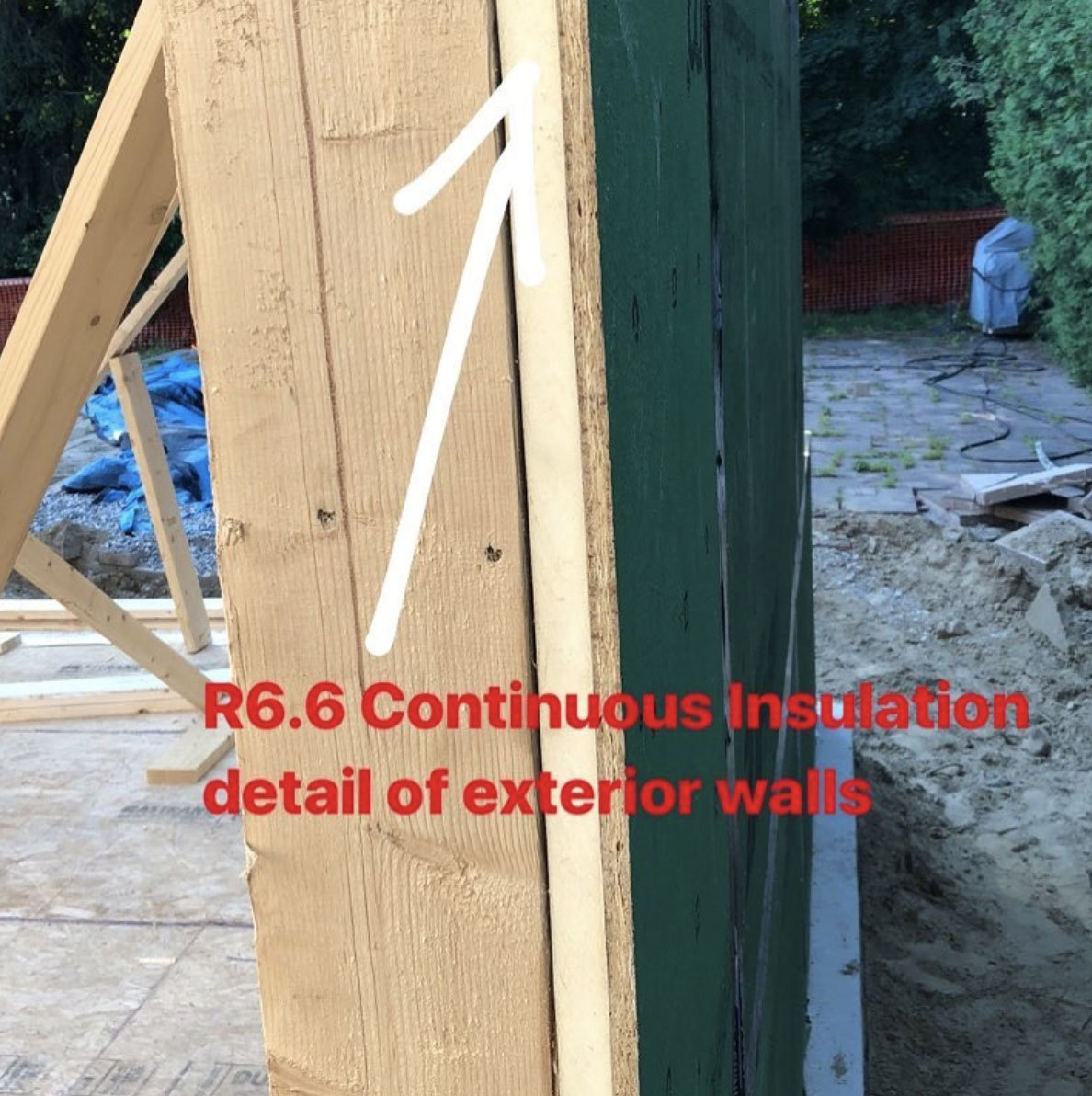

| 1-1/2" | 31 | 6.6 | ||||

| 2" | 23 | 9.6 | ||||

| 2-1/2" | 18 | 12.6 |

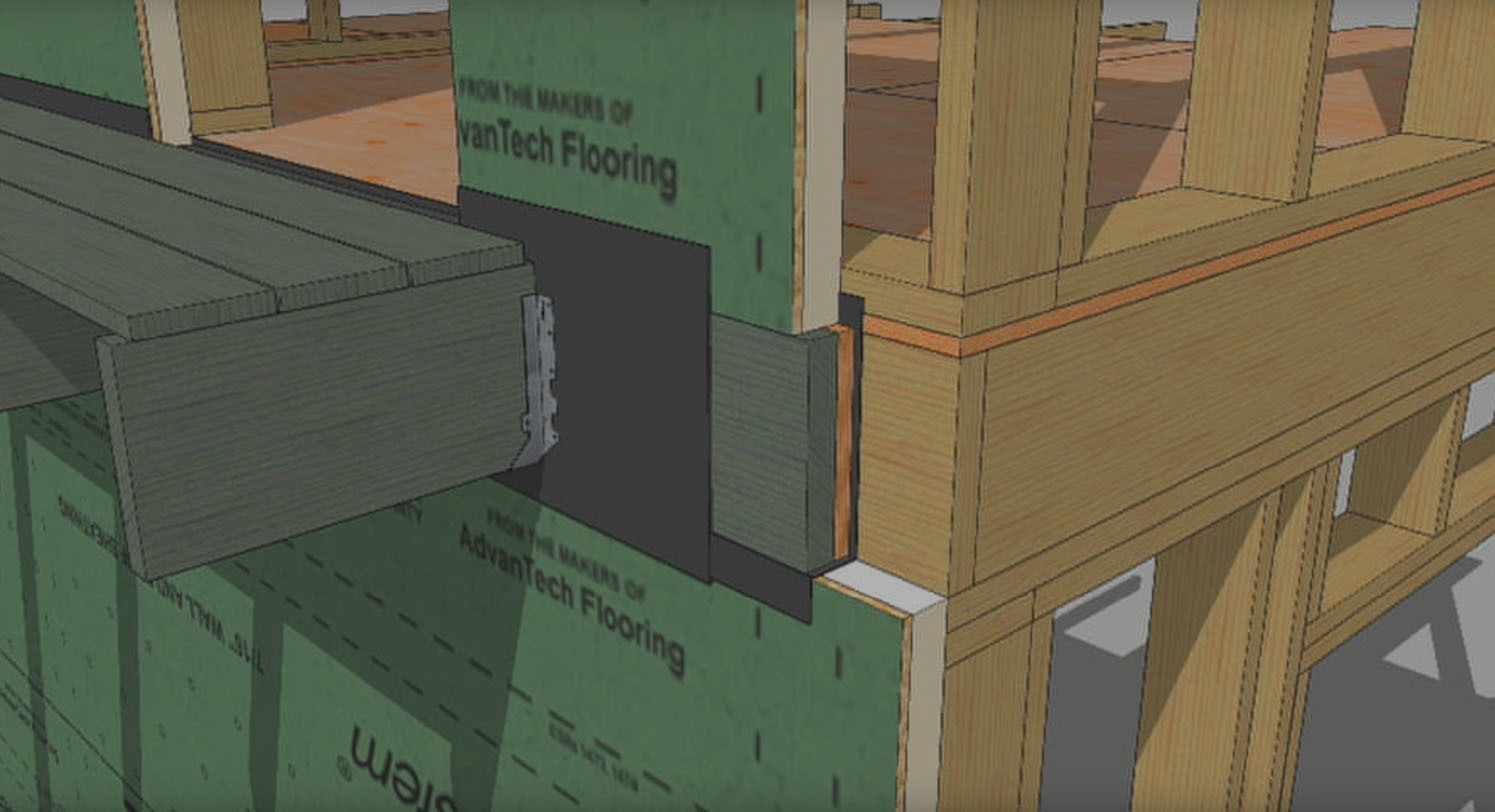

02 How to Install

Installation Videos

Designed to help you streamline exterior wall assemblies, ZIP System R-sheathing is easy to expertly install.

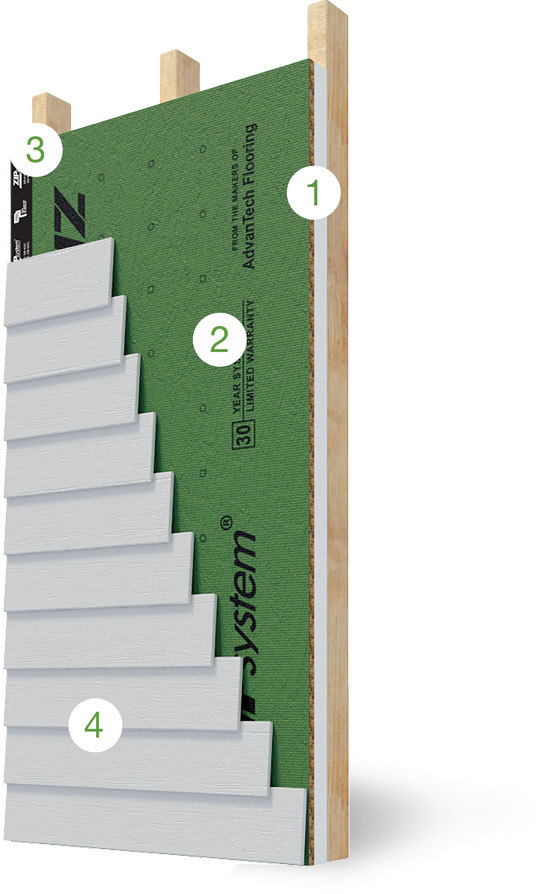

03 Why It Works

The front fights air and moisture. The back fights heat and cold. Together, they knock out the elements.

-

Built-In Exterior Insulation

Polyisocyanurate rigid exterior insulation on the back of the structural panel reduces heat transfer to help keep homes consistently comfortable year-round.

-

Integrated Water-Resistive Barrier

A resin-impregnated, water-resistive barrier manufactured onto the structural panel eliminates the need for housewrap, sheds water to the exterior and is backed by a 180-day Exposure Guarantee[2].

-

Continuous Air Barrier

Sealed seams with advanced acrylic ZIP System tape and ZIP System liquid flash form a continuous air and water barrier that manages water and reduces air leaks for an energy-efficient exterior.

-

Structural Durability

The integrated structural sheathing system meets wall bracing requirements and contributes to shear wall assemblies. Plus, the engineered wood panel provides a nailable, easy-to-flash base.

04 Code Requirements

Take the guesswork out of code.

05 Product Reviews

See what other builders are saying.

With ZIP System R-Sheathing, we are able to essentially terminate ‘thermal bridging’ which is the transfer of heat/cold thru areas of least resistance like common wood on wood framing connections. Hummingbirdhill Homes@hummingbirdhillhomes

Explore more products.

06 News & Articles

Behind the Build Blog

OA Showcase Home Creates Resilient Design with ZIP System® R‑Sheathing

Project giving new life to 1920s-era Minneapolis home

Read MoreQ&A on Continuous Insulation with Green Builder Carl Seville

Carl Seville of SK Collaborative shares his thoughts on the building envelope and the role ZIP System® R-sheathing plays for managing air and thermal bridging.

Read MoreHow to Build a Huge Custom Home with a Continuous Air and Water Barrier

Kentucky-based Atchison Heller goes full fluid-applied flashing for a 13,000-square-foot custom home to achieve a super air- and water-tight building enclosure.

Read MoreFighting Moisture During Renovation and Restoration

Long Island-based builder Paul Patera discusses how he uses ZIP System sheathing and tape for both renovation and restoration projects.

Read More