EXACOR® Wall Sheathing

EXACOR wall sheathing panels are fire-resistant, high-density, structural magnesium oxide cement panels. When used as an exterior wall sheathing, EXACOR® panels can replace other sheathing materials in certain assemblies, potentially reducing the number of layers required.

EXACOR wall sheathing can be used in exterior walls of Type III construction greater than 40 feet in height above grade plane when used in accordance with the applicable NFPA 285–compliant designs as listed in ESL-1290. EXACOR sheathing is not approved for use on Type I or II buildings except as noted in ESR-4635

01 Products

Sheathing Panel, 1/2" × 4' × 8'

| Panel Count | 38 |

| Fire Resistance | ASTM E119, ANSI/UL 263 |

| Structural | ESR-4635 |

Sheathing Panel, 1/2" × 4' × 9'

| Panel Count | 33 |

| Fire Resistance | ASTM E119, ANSI/UL 263 |

| Structural | ESR-4635 |

Sheathing Panel, 1/2" × 4' × 10'

| Panel Count | 32 |

| Fire Resistance | ASTM E119, ANSI/UL 263 |

| Structural | ESR-4635 |

View Specs

| Nominal Product Thickness | Nominal Panel Size | Panel Count | Weight (lbs./sq. ft.) | Max Support Spacing | Edge/Field Spacing[3] | Maximum Allowable Shear Values (plf)[4] [5] [6] [7] [8] [9] | Transverse Wind Loads (psf)[6] [7] [10] | Fire-Resistance-Rated Assemblies[11] | Code Evaluation Report |

|---|---|---|---|---|---|---|---|---|---|

| 1/2" (12 mm) |

4' × 8' 4' × 9' 4' × 10' |

38 33 32 |

2.7 | 24" | 4/6" | 230 | +/-38 | Exterior Load-Bearing Wall: Wall and Partition: MOS-1290-07 (ESL-1290, 2 hours) MOS-1290-08 (ESL-1290, 2 hours) |

ESR 4635 |

02 What Is MgO

Magnesium oxide (MgO) offers simple strength and streamlined installation for a building panel with exceptional workability.

MgO panels are cementitious panels that are primarily made of inorganic materials reinforced with layers of glass fiber mesh. EXACOR® MgO panels are manufactured to provide a streamlined solution for strength, fire resistance and sound performance.

-

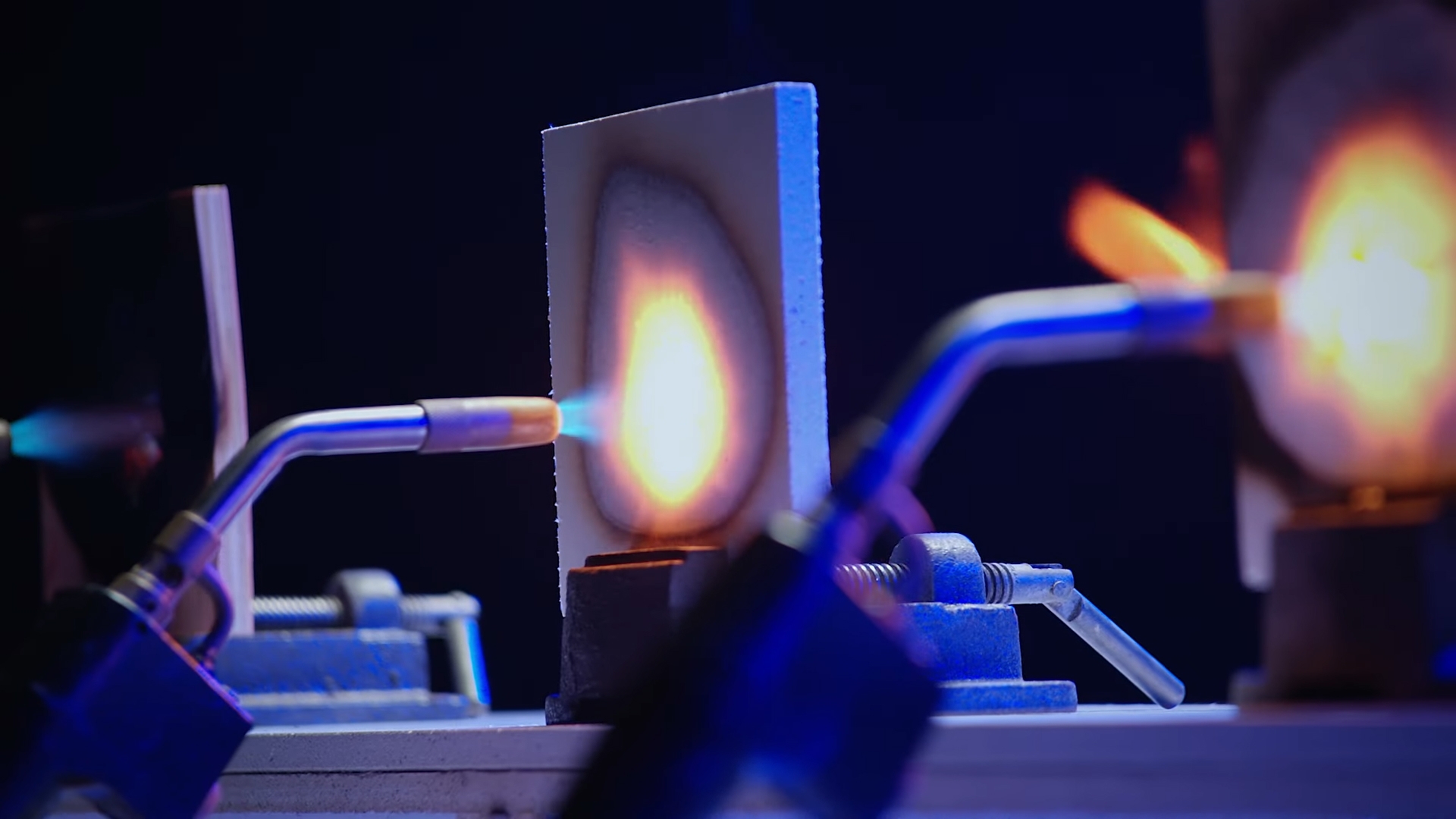

Fire Resistance

Inherently fire resistant throughout and provides fire resistance as part of fire resistance–rated wall and floor/ceiling assemblies.

-

Durability

Tough enough to handle jobsite conditions, withstands exposure to moisture and does not warp, expand, cup or delaminate like other wood panels do.

-

Inherent Strength

Contains a proprietary layered mesh reinforcement for added structural value.

-

Quality Assurance

Manufactured under a quality control program with inspections by ICC-ES and Underwriters Laboratories (UL) to ensure consistent product performance.

-

Optimize Material & Labor Costs

High-performing material that may save time and help reduce materials and trades needed to install.

03 Documents

Resource Library

04 Warranty

Enhanced Experience

If you’re building a multifamily or light commercial project, register your project and complete a preconstruction meeting to access the full range of technical support and warranty benefits for your build, including a transferrable warranty. Review full warranty details and access project registration at the link below.

Explore more products.

05 News & Articles

Behind the Build Blog

How TDK Construction Saves Time and Money with EXACOR® MgO Panels: Getting in on the Ground Level

TDK Construction agrees using EXACOR MgO panels equated to real time savings in a recent luxury apartment community project.

Read More