Your ZIP System Wall Sheathing Questions — Answered

4 Min Read April 29, 2021

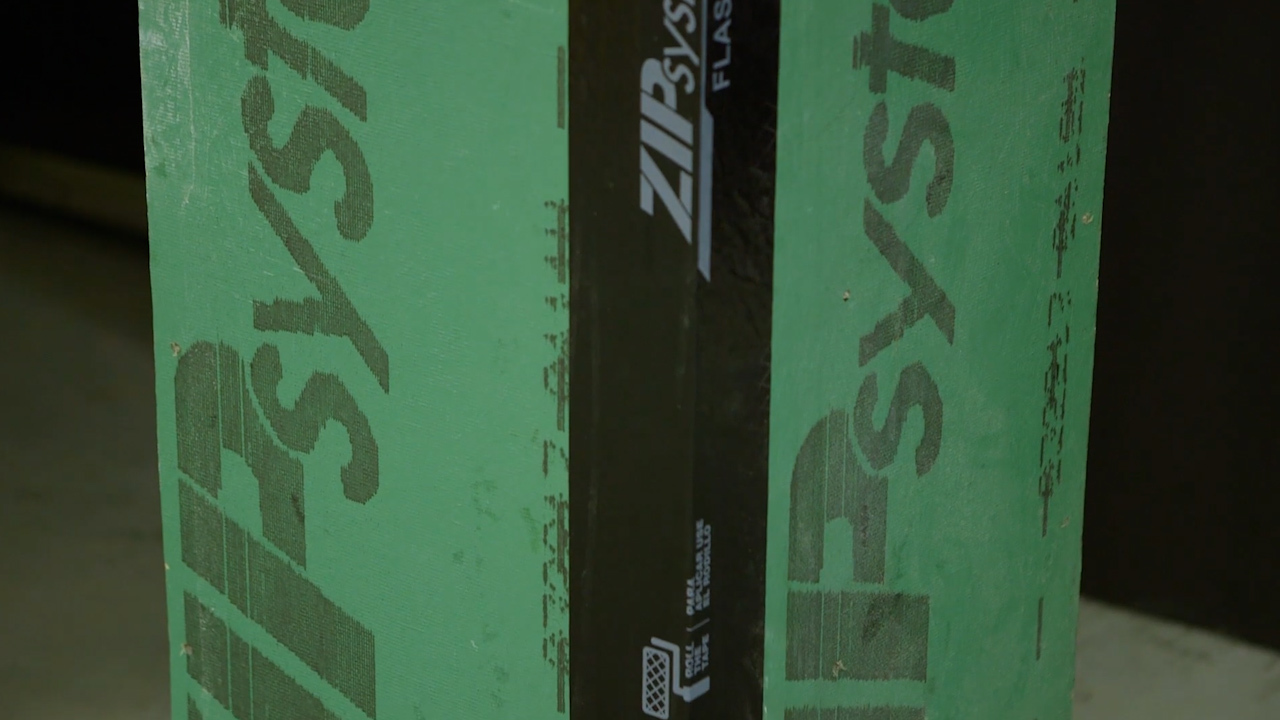

In the US or Canada, you may have seen buildings under construction with green wall sheathing.

The green sheathing boards are one component of a ZIP System™ Building Enclosure. ZIP System Building Enclosures make it easier for builders and framing crews to weatherize and install air barriers. This involves using ZIP System sheathing and sealing solutions in a two-step process.

Below are some common questions regarding ZIP System sheathing, tape and liquid flash products.

What are ZIP System sheathing panels made of?

ZIP System wall panels are made from high-quality, water-resistant OSB. They have a Structural 1 rating for strong shear strength. The manufacturing process integrates a protective water-resistant barrier into the panel.

Are ZIP System sheathing panels pressure treated lumber?

No. ZIP System sheathing panels do not go through a chemical, pressure treating process during manufacturing.

What is the difference between the green and brown ZIP System sheathing panels?

Thickness. Green ZIP System sheathing panels are 7/16” and the sienna (brown or red) panels are 1/2” or 5/8” thick.

How long can ZIP System sheathing and tape be exposed to weather?

ZIP System building enclosure products have a 180-day Exposure Rating.

What is a WRB?

A WRB is a water-resistive barrier (or weather-resistive barrier). It stops water from getting into wall assemblies by creating a barrier between the structural wall and the outside covering. The building code requires at least one layer of WRB throughout North America.

Does ZIP System need to be covered with housewrap?

Not in most cases. The integrated overlay on ZIP System sheathing meets WRB code requirements. Sealed seams using ZIP System tape or liquid flash are also effective. This can eliminate the need for housewrap in many cases.

Can you install housewrap over ZIP System?

Yes. Some exterior claddings (such as stucco) require multiple WRB layers.

ZIP System sheathing and tape counts as one WRB layer, so in assemblies in which an additional WRB layer is required by code or the cladding manufacturer, housewrap or another WRB layer will need to be installed.

More information on ZIP System and stucco can be found in the Technical Library.

What fasteners can be used with ZIP System wall sheathing?

Fasteners approved for regular sheathing can also be used with ZIP System wall sheathing to attach panels to the frame. Screws are not recognized as an acceptable fastener for installing structural sheathing like ZIP System to wood framing.

What about all the fastener holes in the ZIP System panel?

Although some builders like the belt and suspenders approach of covering all the nail heads in the panel field with ZIP System liquid flash, it is not a requirement for the ZIP System warranty. Fasteners that miss the framing or go more than half way through the panel, should be addressed, but, other than these, the vast majority of nail heads should not be an issue.

Is ZIP System an air barrier?

ZIP System sheathing, along with ZIP System flashing tape or liquid flash, creates a strong air barrier. This helps control air flow effectively. In addition, ZIP System flashing products can be used in some details to tie in other components of the air control layer for the building.

How many rolls of ZIP System flashing tape are needed per panel?

On average, one 90’ roll of ZIP System flashing tape can flash the panel seams of six to seven standard 4’x8’ panels on a flat wall, depending on the experience level of the framer.

Are ZIP System sheathing panels a vapor barrier?

No, the integrated protective overlay of a ZIP System wall sheathing panel is permeable to allow for drying to the outside.

What’s the permeability of ZIP System sheathing panels?

The permeability of the entire panel is based on the permeability of the OSB (1-3 perms depending on thickness), while the permeability of the integrated protective overlay alone is 12-16 perms.

Can you paint over ZIP System sheathing panels?

It is not recommended or warranted. We advise against adding extra coatings like paint to ZIP System sheathing panels.

- What are ZIP System sheathing panels made of?

- Are ZIP System sheathing panels pressure treated lumber?

- What is the difference between the green and brown ZIP System sheathing panels?

- How long can ZIP System sheathing and tape be exposed to weather?

- What is a WRB?

- Does ZIP System need to be covered with housewrap?

- Can you install housewrap over ZIP System?

- What fasteners can be used with ZIP System wall sheathing?

- What about all the fastener holes in the ZIP System panel?

- Is ZIP System an air barrier?

- How many rolls of ZIP System flashing tape are needed per panel?

- Are ZIP System sheathing panels a vapor barrier?

- What’s the permeability of ZIP System sheathing panels?

Have more questions? Contact the Huber Engineered Woods Technical Support Team or download the ZIP System Building Enclosures Installation Manual.