The Role of EXACOR® Underlayment in Simplifying Urban Multifamily Projects

5 Min Read July 15, 2025

For their seven-unit East Boston condo, Phoenix Homes Boston trusts EXACOR underlayment to save time, streamline installation, and deliver lasting performance.

Building in urban environments such as Boston presents a unique set of challenges for multifamily builders: tight jobsites, demanding timelines and the need for durable, high-performance materials that simplify the construction process. EXACOR® underlayment panels offer a base for floor coverings that eliminates the need for gypsum underlayment and installs 30% faster than gypsum underlayment.

For developers such as Gary Carter, owner and project manager for Phoenix Homes Boston, the decision to prioritize ease of installation was a core focus from day one. His seven-unit condo project on 47 Condor Street in East Boston required a solution that would eliminate unnecessary steps while withstanding jobsite wear and tear in an urban environment. Read on to see how Carter’s strategic use of EXACOR® panels became a pivotal factor in securing both the efficiency and success of the project.

What makes EXACOR underlayment superior to gypsum concrete?

Many multifamily projects default to gypsum concrete for underlayment, but that’s not always the most efficient choice. The material requires extra coatings, longer installation times and brings more trades into the mix, creating a messier, more complicated jobsite. Gary Carter wanted something simpler and cleaner.

“EXACOR panels offer a solid, stable surface from installation through project completion, holding up under foot traffic and material handling without breaking down over time,” Carter said.

Carter’s experience reflects a larger shift in the construction industry toward innovative materials such as magnesium oxide boards. Known for their strength, fire resistance and sound performance, EXACOR® MgO panels offer a streamlined alternative to gypsum concrete, helping builders work faster and keep jobsites cleaner, without sacrificing performance.

4 Key Benefits of EXACOR Underlayment

1. Time Savings and Ease of Installation

EXACOR underlayment eliminates the extra steps that come with traditional options such as gypsum concrete. With EXACOR, panels are first glued and fastened, then prepped for finished flooring installation according to the floor manufacturer’s guidelines with no need for extended drying times or additional trades.

Carter experienced this firsthand noting, “EXACOR is a far easier application with fewer steps and gives the same results.”

Unlike gypsum concrete, which requires mixing, pouring, leveling, drying and often additional sealing or finishing, EXACOR underlayment’s streamlined installation process translates to a faster, drier and smarter process that helps projects stay on schedule and avoid costly delays.

2. Durability

Jobsites face tough weather conditions, such as wind, rain, snow and more, making it essential to choose materials that can withstand the elements during construction. Made with magnesium oxide and an integrated mesh core, the MgO structural panels are designed to withstand exposure to moisture without warping, expanding, cupping or delaminating, which are common issues with wood-based panels.

“Once you put the [EXACOR] panel down, it just stays the same like the first day you put it down. It doesn’t deteriorate,” Carter said.

With an exposure period of up to 200 days, EXACOR panels hold strong through the toughest weather, reducing the risk of damage, waste and replacement costs. Learn more about this product’s warranty and durability on our website.

3. Sound Absorption

Noise control is essential in multifamily buildings, and EXACOR underlayment helps create quieter spaces. Its sound-dampening properties contribute to meeting key sound transmission (STC) and impact insulation (IIC) class ratings, often without the need for an additional sound mat. Unlike many gypsum-based assemblies, which typically require a sound mat to meet the same acoustic ratings, EXACOR underlayment provides a streamlined solution that simplifies installation.

“The sound deadening was key,” Carter explained. “Without that aspect, I wouldn’t have been able to use it on the floors. The plans called for something that met both the fire resistance requirements and the sound deadening.”

4. Fire Resistance

In dense urban environments like Boston, fire resistance is an essential characteristic for walls. For this project, Carter used both EXACOR wall sheathing panels and EXACOR underlayment panels

“Given EXACOR’s structural integrity, we were able to use just one sheet of the EXACOR® wall sheathing, which reduced a step and the extra cost of adding two layers to the outside, like you would have to with traditional wood-based wall sheathing materials,” Carter said.

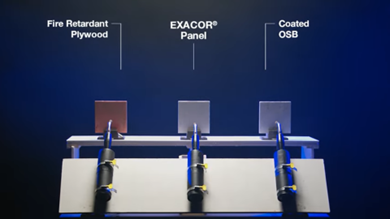

Compared to traditional materials such as treated plywood and coated OSB, EXACOR wall sheathing panels offer superior resistance to flames. Watch this demonstration to see how EXACOR wall sheathing panels stand up to fire compared to traditional fire-treated plywood and coated OSB.

“Given the close proximity, if they were to have a fire, that fire is not going to transfer into our building,” Carter said. “Or, at the least, we’re going to have the fire resistance needed to delay the spread until the fire department can get there in time to put it out.”

Why Multifamily Builders Should Choose EXACOR Products for Urban Environments

EXACOR underlayment is an ideal all-in-one solution for multifamily projects, combining time savings, sound dampening and easy installation in a single product. With its ability to save up to 30% more installation time than other underlayment methods, EXACOR underlayment makes faster, easier installs possible, without the extra steps, whether you’re building a bustling city condominium or a suburban multifamily development.

Ready to get the product into your hands and onto your jobsite? Get a free sample of EXACOR underlayment and discover its unmatched installation process.

Simplify installation in your multifamily build with EXACOR panels.

Request a free 1/2" sample now.