ZIP System® Wall Sheathing

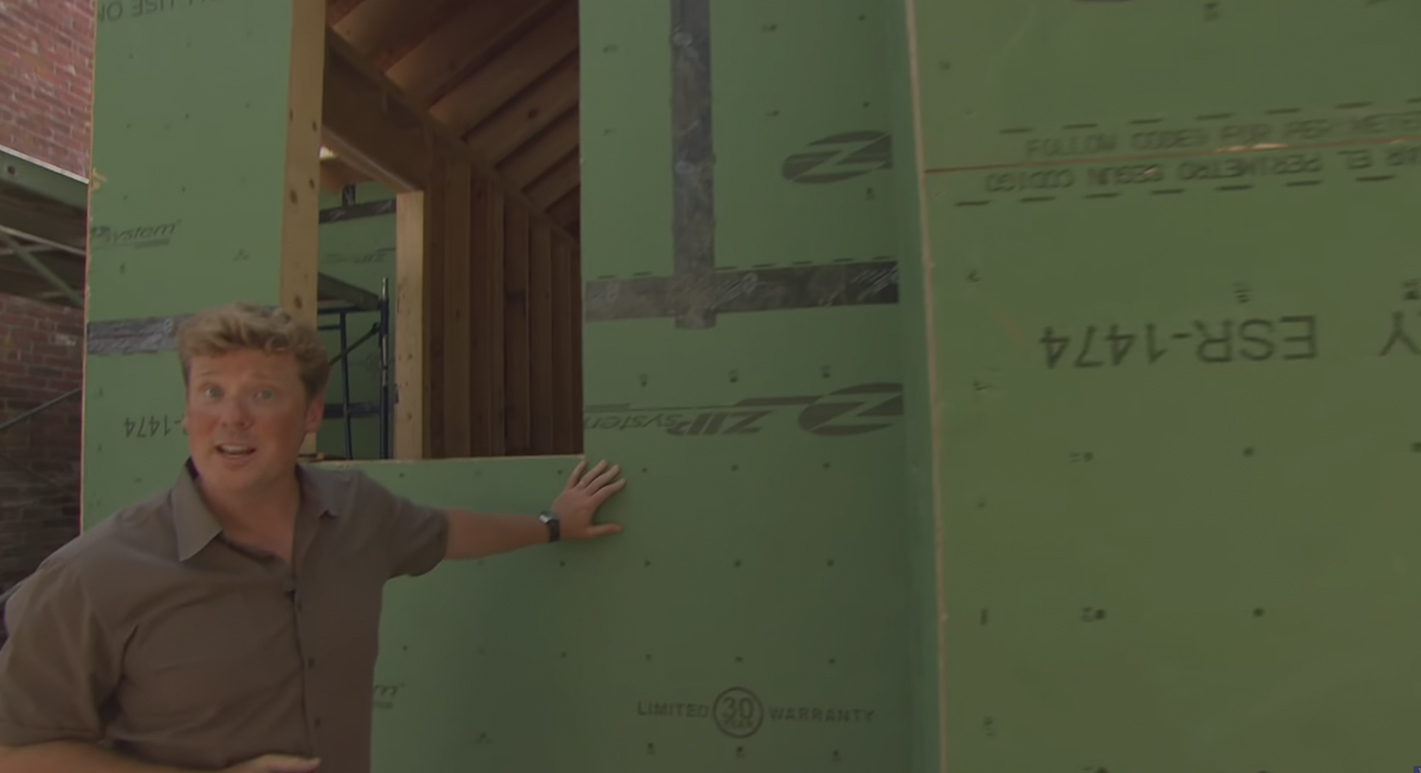

A revolutionary new approach to building enclosures, ZIP System® sheathing and tape streamlines the weatherization process with an integrated air and water-resistive barrier that delivers moisture and air protection in one easy-to-install system.

01 Products

7/16" Long Length Wall Sheathing, 4' × 10'

| Panel Count | 70 |

| PS 2 Span Rating | 24/16 Structural 1 |

7/16" Long Length Wall Sheathing, 4' × 10' 1-1/8"

| Panel Count | 60 |

| PS 2 Span Rating | 24/16 Structural 1 |

View Specs

Performance Category | Panel Size | Panel Count | PS 2 Span Rating | Code Evaluation Report | Vapor Transmission of WRB Layer | Air Barrier Assembly |

|---|---|---|---|---|---|---|

7/16" Panel

7/16" Panel | 4' × 8' | 80 | 24/16 Structural 1 | ESR 1473 ESR 1474 | 12 Perms ASTM E 96 Procedure B | ASTM E 2357 <0.037 L/s●m2) @ 75 Pa for Infiltration ASTM E 2357 <0.012 L/s●m2) @ 75 Pa for Exfiltration |

1/2" Panel

1/2" Panel | 4' × 8' | 70 | 32/16 Structural 1 | |||

5/8" Panel

5/8" Panel | 4' × 8' | 55 | 40/20 Structural 1 |

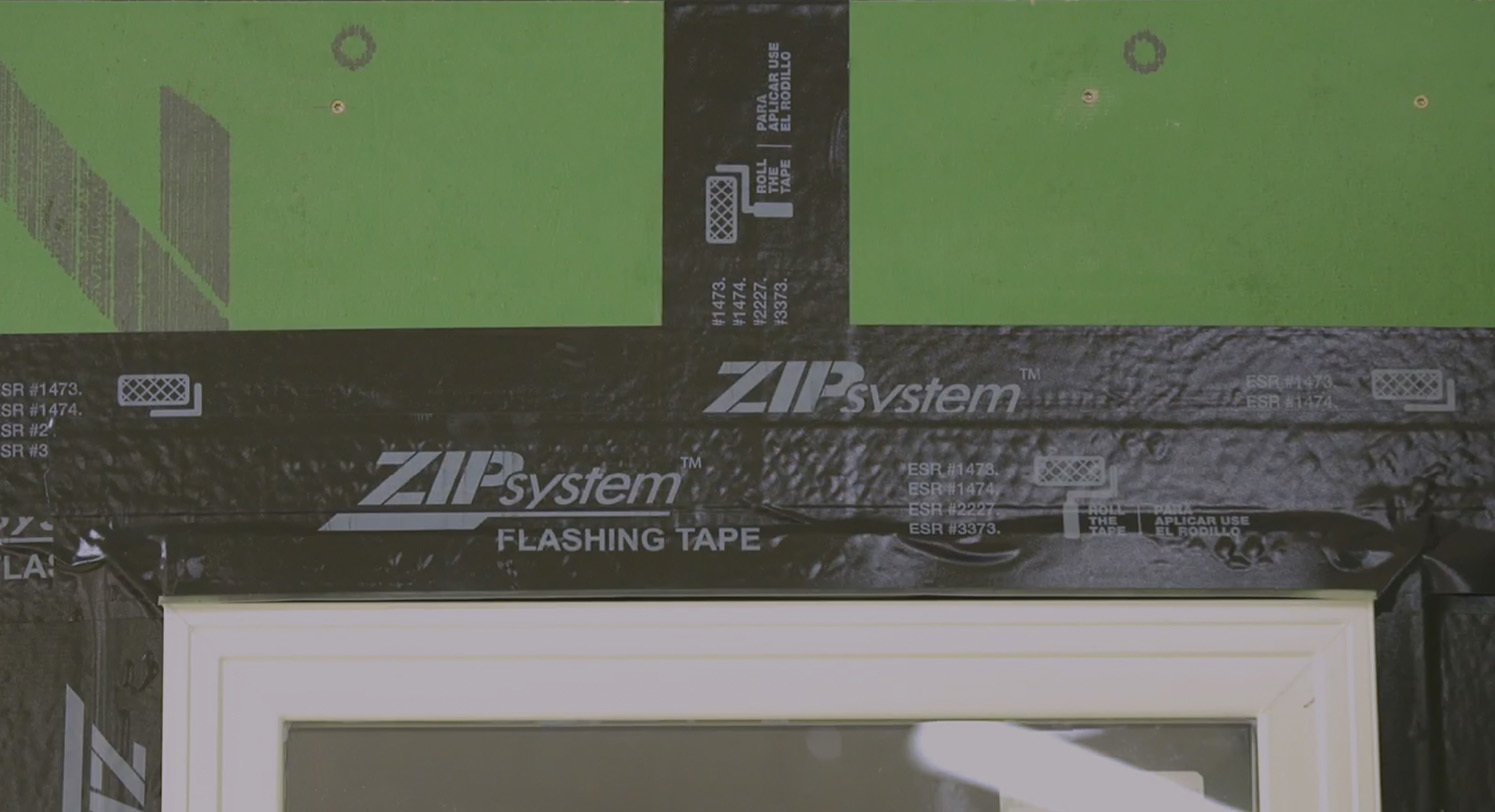

02 How to Install

Installation Videos

Watch simple step-by-step instructions and proper techniques to learn how to apply ZIP System wall sheathing and tape.

03 Why It Works

We introduced the integrated sheathing category. Here’s how building enclosures have evolved.

-

Structural Durability

ZIP System® panels are available with a Structural 1 rating, so you can get shear strength to meet seismic and high-wind-zone requirements.

-

Integrated Water-Resistive Barrier

By keeping bulk water out but allowing water vapor to pass through, ZIP System® sheathing achieves a delicate balance of water protection and drying potential.

-

Continuous Air Barrier

ZIP System sheathing and tape forms a tight barrier against unwanted air leakage, for a durable building envelope that helps promote energy efficiency and increase interior comfort.

-

Speed & Ease of Installation

Quick and simple two-step installation eliminates the need for housewrap, helping to save money on labor costs and improve project cycle times.

-

Quicker Rough Dry-In

Simply install the panels and tape the seams to achieve a quicker rough dry-in, allowing mechanicals and other trades to start sooner.

-

30-Year Limited Warranty

The ZIP System product line is backed by a 30-year limited warranty and 180-day Exposure Guarantee[1].

-

Award-Winning Quality

ZIP System wall sheathing and tape has been rated #1 in quality every year since 2015 in BUILDER magazine's Annual Brand Use Studies[2].

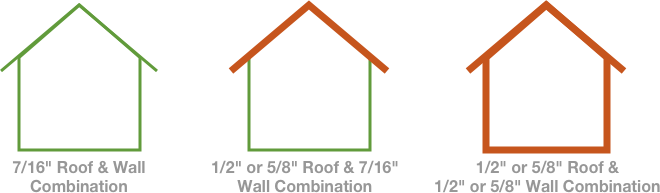

ZIP System® building enclosures are designed to streamline design and construction.

With integrated structural, water and air management layers, ZIP System products offer interchangeable options for optimal roof and wall performance. Three panel thicknesses with various dimensional options let you choose the right panel for each design and application. All sizes are engineered to provide optimal roof and wall performance.

SAMPLE COMBINATIONS

04 Product Reviews

See what other builders are saying.

05 News & Articles

Behind the Build Blog

Your ZIP System Wall Sheathing Questions — Answered

Answers to some common questions regarding ZIP System sheathing, tape and liquid flash products.

Read MoreMaster the Basics for Using ZIP System® Sheathing and Tape

Read on to learn the 3 top tips for seam sealing and transitional details.

Read MoreZIP System® Sheathing and Tape Transforms Multifamily Apartment Project

Why architect Mike Reardon started using an alternative to housewrap.

Read MoreBuilding Science: An Evolution

A look at the progression of the building industry and revolutionary products that paved the way for innovation.

Read MoreHow to Build a Huge Custom Home with a Continuous Air and Water Barrier

Kentucky-based Atchison Heller goes full fluid-applied flashing for a 13,000-square-foot custom home to achieve a super air- and water-tight building enclosure.

Read More