Shuqualak Mill

Huber Engineered Woods

a J.M. Huber Corporation Company

Supporting industry and bringing jobs while caring for our environment.

Huber Engineered Woods’ (HEW) most efficient and sustainable oriented strand board facility is being planned for Shuqualak, Mississippi. This new mill will be the sixth in HEW’s national footprint and its first in Mississippi.

The Shuqualak Mill will be located on more than 550 acres and will bring more than 150 direct jobs to the area with exponential business for adjacent industries, including logging and trucking.

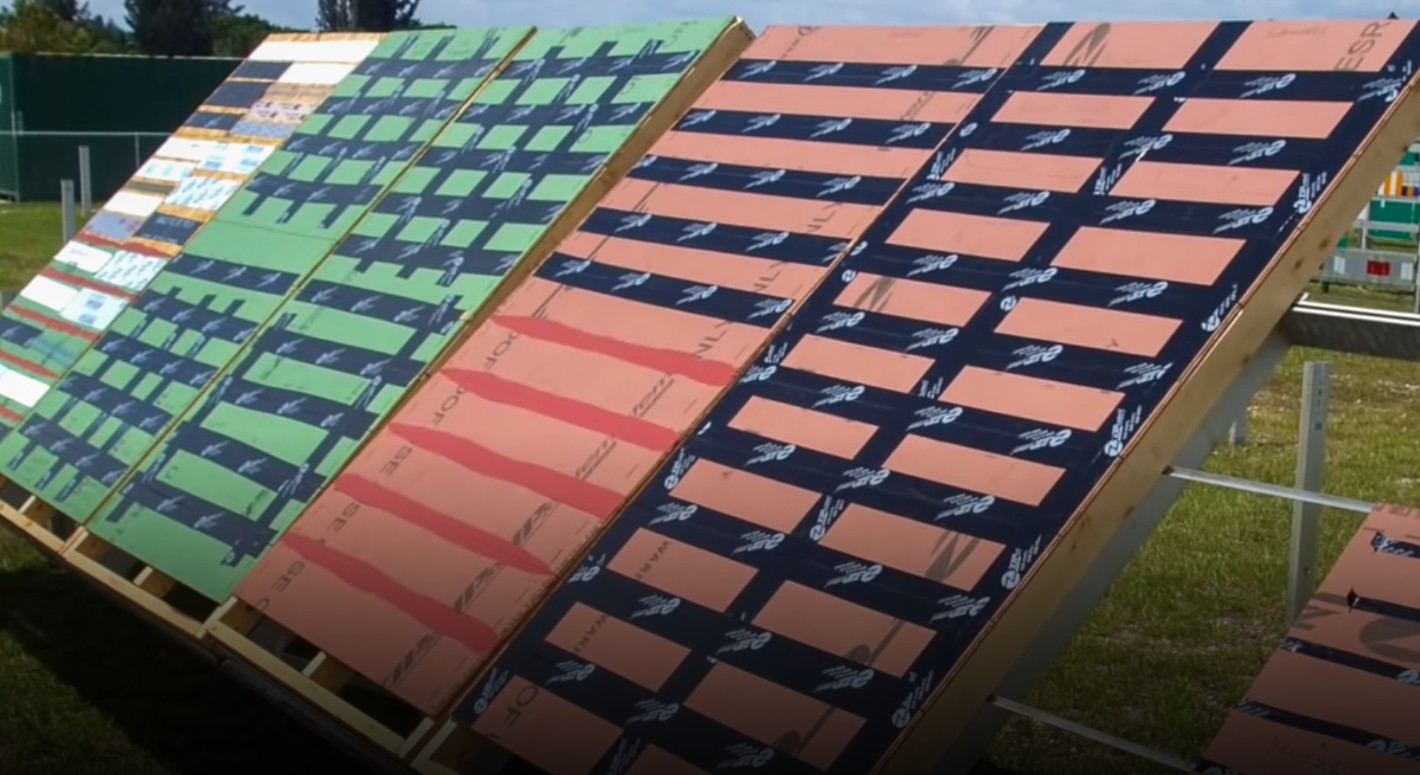

HEW’s new Shuqualak Mill will produce millions of square feet of engineered wood panel products to support the nation’s need for structural building materials and meet the demands of our nationwide network of building materials distributors and lumberyards. Located adjacent to an existing railroad that will allow access to an environmentally friendly product shipment and material delivery, the new mill will also feature advanced technology that will help HEW further reduce its environmental impact.

Part of one of the largest and longest-running family-owned companies in the United States, HEW is a respected producer of high-performance, quality products, including ZIP System™ building enclosures and AdvanTech® subflooring, which have revolutionized the construction industry.

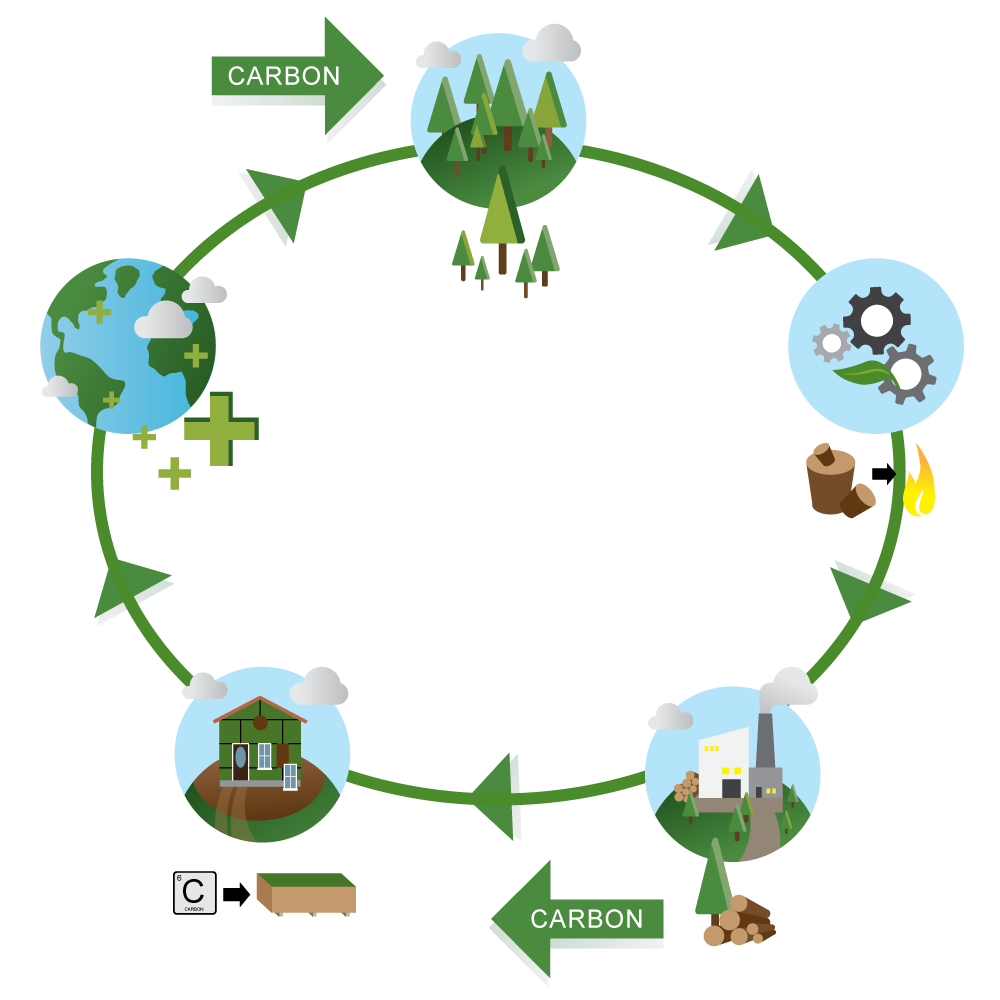

Huber Engineered Woods’ manufacturing is focused on reducing energy consumption, sustaining forests and providing a positive net carbon impact.

-

Sustainably Harvested Southern Yellow Pine

Our operations exist alongside and help maintain healthy and sustainable forests with proximity to fast-growing trees.

-

Recycled Waste as a Fuel Source

Bark and trimmings are recycled into fuel, reducing plant air emissions related to heating and drying processes. The majority of HEW plants are zero waste to landfill operations.

-

Water- and Energy-Saving Technology

Recirculated gas, advanced waterless components, waste reuse, LED lighting and responsive, energy-conserving electrical equipment are a few of the environmentally forward implementations that make HEW’s newest operational designs some of the most sustainable in the country.

-

Stored Carbon in Finished Products

HEW’s engineered wood panel products store, for their lifetime, carbon that has been sequestered from the atmosphere by trees.

-

Net Positive Carbon Impact

Ultimately, net emissions from HEW’s plant operations provide a net carbon reduction to the environment annually.

-

Sustainably Harvested Southern Yellow Pine

Our operations exist alongside and help maintain healthy and sustainable forests with proximity to fast-growing trees.

-

Recycled Waste as a Fuel Source

Bark and trimmings are recycled into fuel, reducing plant air emissions related to heating and drying processes. The majority of HEW plants are zero waste to landfill operations.

-

Water- and Energy-Saving Technology

Recirculated gas, advanced waterless components, waste reuse, LED lighting and responsive, energy-conserving electrical equipment are a few of the environmentally forward implementations that make HEW’s newest operational designs some of the most sustainable in the country.

-

Stored Carbon in Finished Products

HEW’s engineered wood panel products store, for their lifetime, carbon that has been sequestered from the atmosphere by trees.

-

Net Positive Carbon Impact

Ultimately, net emissions from HEW’s plant operations provide a net carbon reduction to the environment annually.

The Huber Principles: The Bedrock of Our Business

As a Huber company, Huber Engineered Woods leads with a focus on integrity. The trust of our customers, shareholders and communities is dependent upon our collective actions and decisions. These are rooted in our commitment to the Huber Principles that guide forward-thinking, high-standard practices to uphold the J.M. Huber Corporation reputation that has been built over 140 years.

Leadership with Care

We never settle for the expected or status quo. We are on a quest for methods that deliver the highest-quality products, consistent service and positive experiences for customers and employees alike. From the scientist in our lab and skilled operator in our mill to the net-zero builder and community designer, we are committed to being a company that respects and serves people through an innovative mindset in all we do.

An Innovation Leader

Innovation is a driving force at Huber Engineered Woods and the fuel behind our industry-changing product solutions and standard-setting operations. Headquartered in Charlotte, North Carolina, with a dedicated R&D facility in Commerce, Georgia, and manufacturing plants in Maine, Georgia, Virginia, Tennessee and Oklahoma, we pride ourselves on being part of an organization recognized as a “US Best Managed Company.”

Community Support

At Huber Engineered Woods, service extends beyond our product operations and sales to our philanthropic spirit. J.M. Huber Corporation gives 1% of its net annual income to various organizations to support affordable housing, education and wellness, and environmental sustainability.

Habitat for Humanity

Significant product donations are contributed each year, in addition to hands-on volunteering throughout the country by Huber employees, to support this organization near and dear to Huber Engineered Woods’ business.

Gary Sinise Foundation

A proud employer of many veteran men and women, Huber Engineered Woods supports materials and funding for adaptive housing for severely wounded veterans and first responders and their families.

Arbor Day Foundation

J.M. Huber Corporation is a yearly sponsor of the Arbor Day Foundation and provides annual funding for reforestation projects around the globe to further Arbor Day’s mission to make the planet greener and healthier.

Project Lead the Way

A significant sponsor of Project Lead the Way, J.M. Huber Corporation works with this national organization to make STEM education available to children in elementary, middle and high schools across the country, many of whom are from underprivileged backgrounds.

News

Recent Press Releases

J.M. Huber Corporation Recognized as a US Best Managed Company Gold Standard Honoree

J.M. Huber Corporation (Huber) is proud to announce it has been selected as a 2023 US Best Managed Company Gold Standard honoree. Sponsored by Deloitte* Private and The Wall Street Journal, the program recognizes outstanding US private companies and the achievements of their management teams.

Read MoreHuber Sponsors Empowerment Workshops for Survivors of Fallen Heroes

J.M. Huber Corporation (Huber), one of the largest family-owned companies based in the United States, announced today that it has donated $500,000 to the Gary Sinise Foundation (GSF) to fund their Empowerment Workshops program for surviving spouses and children of fallen soldiers.

Read MoreHuber Resources Corp. Acquires Compass Land Consultants

Huber Resources Corp. (“HRC”) announced today the acquisition of certain assets of Compass Land Consultants, Inc. (“CLC”), which will grow and expand HRC’s as well as their Sewall Forestry and Natural Resources Consulting (“SFNR”) business globally in key service areas including timberland management, timberland appraisals, forest inventory management, and forest modeling.

Read MoreLiving by the Huber Principles 2022 Impact Report Now Available

This report tells the story of what our high-performing teams have accomplished over the past year in the spirit of the Huber Principles, which define our culture.

Read More